We garner materials according to or as close as possible to the customer's specification. For the most part, metal rolling rods are 12 or 6 m long. Cutting is done with an abrasive wheel, band saw or autogen (gas burner).

We garner materials according to or as close as possible to the customer's specification. For the most part, metal rolling rods are 12 or 6 m long. Cutting is done with an abrasive wheel, band saw or autogen (gas burner).

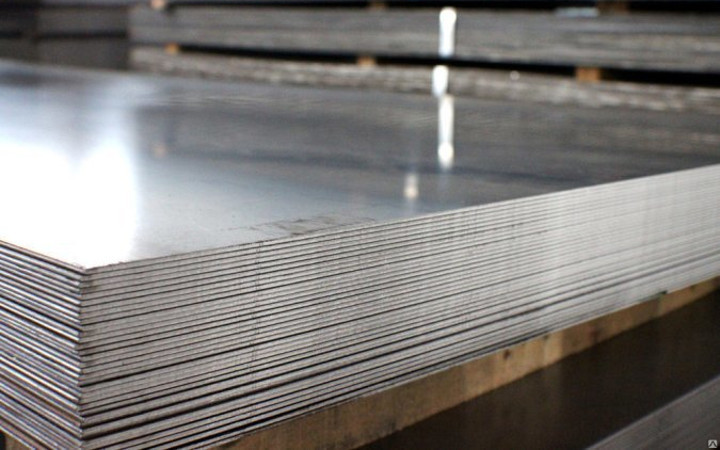

You can cut specific details. This service is mainly concerned with cutting steel sheets. Sheet materials are cut with industrial metal guillotine, laser and plasma (both outsourced). Custom cutting of aluminium stainless steel sheet materials is also possible. Cutting options from 0.5 mm to 150 mm. Customer drawing is preferred.

We offer bending of rebars on the workbench. It is possible to create rebars in bending shapes from reinforcement strings with a diameter of 6 mm to 32 mm. The most popular products are rebar fittings, L-shaped parts, C-type clamps, U-shaped clamps, etc. It’s desirable that clients provide their own conceptual design sketch.

We provide drilling services in steel profiles and sheet materials. It is possible to form holes, both with a stationary drill machine and with a magnetic crown drill/milling machine. Our experience also allows for the realization of builders' whims such as longitudinal drills with plasma or laser (both outsourced) and large-scale drills in flanches or sheet mouldings. Customer drawing is preferred.

In the field of metal processing, plasma cutting services have become popular thanks to the economics of this method and the Atras Veiksans. The nature of the technology is as follows: compressed high pressure air is fed, the electrodes form an electric arc which, when interacting with air, is transformed into plasma -- ionized high temperature gas.

Stainless steel products - component parts, structures, furniture - have a high level of reliability and long life compared to other types of metallic materials. Our company offers to purchase both custom-made stainless-steel products and products made according to individual orders - ranging from household items to industrial designs of any complexity, including non-standard solutions, based on your drawings and sketches.

In order to obtain a high-quality iron sheet, hot-rolling or cold-rolling technologies are used, followed by a heat treatment and galvanizing of the material surface to protect it against corrosion and harmful external factors. Hot-rolled sheets are more commonly used in mechanical engineering for the production of internal components, as well as for the construction of metal structures of profiles.

Mechanical cutting of metal is the processing of products using disc and press cutters, circular saws, guillotine, drills and other mechanical tools.

Drilling in the sheet metal is done using special drills that create holes of the required depth and diameter.